Office Address

Ruko Venice, Golf Lake Residence No.11 B3-B5, Cengkareng Tim., Kecamatan Cengkareng, Kota Jakarta Barat, Daerah Khusus Ibukota Jakarta

Phone: 0852 827195

Office Address

Ruko Venice, Golf Lake Residence No.11 B3-B5, Cengkareng Tim., Kecamatan Cengkareng, Kota Jakarta Barat, Daerah Khusus Ibukota Jakarta

Phone: 0852 827195

Country: China

Industry: Network cabinet manufacturing

Original Equipment: Traditional CNC press brakes and CO2 laser cutters

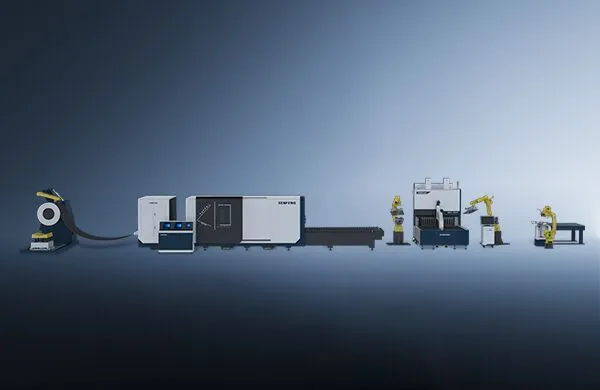

SENFENG Solutions: Three BDC2500 flexible panel benders, six laser blanking lines like 1503CLH coil laser cutting machine for 0.6-3mm aluminum and 2012CH coil laser blanking line for 8-14mm steel

Driven by the digital era, industries such as data center, 5G communication, new energy and industrial automation are expanding rapidly. This growth fuels demands for advanced network infrastructure. As a key component of such infrastructure, network cabinet serves a critical role in housing server, communication module and power supply system. Their manufacturing has evolved into a process requiring small-batch, high-mix, high-precision, and fast-turnaround production.

To adapt to this trend, many cabinet manufacturers are turning to one-stop laser processing solutions, in order to enable full automation from sheet cutting to bending. The goal is to boost flexibility, production efficiency and product quality while handling diversified customer needs.

The customer in this case is a mid-to-large-scale network equipment manufacturer based in the East China, operating a 30,000+m2 facility with over 200 employees. Their core product line includes server cabinet, industrial control cabinet, 5G communication enclosure and power supply cabinet, which has served sectors like telecommunication, energy, transportation and government enterprises.

Facing rising competition and increasing demands for both shorter delivery cycle and higher product consistency, the company decided in 2024 to upgrade its core production line with smart automation. They purchased 3 fully–automatic panel benders and 6 high-end laser blanking lines with auto-loading/unloading devices from SENFENG.

In the past, the customer relied on conventional CNC press brakes and CO2 laser cutters, leading to several issues:

SENFENG’s intelligent sheet metalworking solutions can offer key benefits below:

In late 2024, SENFENG’s technician team arrived onsite to install these new panel benders and laser blanking lines, together with commissioning. A phased approach was taken to ensure smooth integration with existing devices, so that they are placed in right place based on existing production flow.

Once these machines were successfully installed, our engineers:

The free-charged training lasted two weeks in total. As a result, through hands-on practice, the customer’s workers quickly gained confidence and were able to operate these machines independently.

After putting into operation, the customer reported the following key improvements after six months:

Within the half year, the customer secured new overseas contracts, and expanded their market shares in South America, the Middle East and Southeast Asia.

To enhance information flow and operational synergy, SENFENG incorporated MES system interfaces across the production lines. All panel benders and laser blanking lines are now interconnected to enable real-time communication of cutting data, machine status and production orders, which will certainly significantly improve process coordination and traceability.

In addition, operators are entitled to manage and monitor all machines through smart touchscreen terminals. Remote diagnostics and maintenance systems also make after-sales service response much faster than before.

Following deployment, SENFENG surveyed front-line workers. Most reported:

SENFENG engineers continue to provide monthly remote check-ins to maintain optimal operation and support staff adaptation.

Our internal statistics showed that ROI cycle for these smart production lines is expected to be under 12 months. With gradual stabilization of production, the customer plans to add two more laser blanking lines within 1–2 years, so that he can integrate them with other automated welding and assembly lines towards a more fully unmanned workshop.

SENFENG will also continue to refine its modular equipment and control systems in line with industry trends, offering more scalable and upgrade-ready solutions.

Through close collaboration with SENFENG, this network cabinet manufacturer has achieved a strategic transformation towards flexibility, efficiency and intelligence. Their delivery capabilities have improved, along with higher competitiveness in global markets.

This marks not just a machine upgrade, but also a pivotal move for the customer toward intelligent manufacturing. SENFENG remains customer-focused and innovation-driven, with the aim of empowering global manufacturers with cutting-edge technology and service to transform their production landscape.